The birth of Yongmao STT3930-200t super large flat-top tower crane

Carefully selected

Since February 2018, CCCC Second Highway Engineering Bureau Co., Ltd. has conducted a 9-month strict inspection and audit on several manufacturers qualified to produce super-large tower cranes such as Fushun Yongmao Construction Machinery Co., Ltd. In the end, Yongmao Construction Machinery designed a new super-large flat-top tower crane STT3930 for the large-scale bridge construction project of CCCC Second Public Office through demand research, optimization design and technological innovation. The product has strong performance, the maximum arm length is 90 meters, the maximum lifting capacity is 200t, and the full-load lifting speed is internationally leading. Yongmao's strong technical strength and excellent product quality left a good impression on CCCC Second Public Office. In the end, CCCC Second Public Security Bureau selected Yongmao STT3930 as the main hoisting equipment for the Nanjing Puyi Highway Cross-river Bridge. The official signing ceremony was held in May.

Successfully signed

On the morning of November 6, 2018, the signing ceremony of the order of Yongmao STT3930-200t tower crane by CCCC Second Highway Engineering Bureau Co., Ltd. was held in Fushun Yongmao Construction Machinery Company.

CCCC Second Highway Engineering Bureau Co., Ltd. is a leader in highway and bridge engineering construction in the industry, and has participated in dozens of key projects such as bridges, tunnels, and railways at home and abroad, including Kenya's Mombasa-Nairobi Railway, Dalian Xinghaiwan Bridge, and Hong Kong-Zhuhai-Macao Bridge. and other key projects that attract worldwide attention. The contracted Yongmao STT3930-200t tower crane will serve as the main hoisting equipment for the Nanjing Puyi Highway Cross-river Bridge. The cooperation between central enterprises and private enterprises is also the best practice for the state to encourage vigorous development of the private economy.

Strict supervision

During the manufacturing process of nearly 3 months after the signing of the contract, the CCCC Second Public Office and the supervising unit entered the factory to conduct comprehensive supervision of the STT3930 tower crane. , The high-demand state ensures the manufacturing quality and manufacturing progress of the STT3930 tower crane. With the joint efforts of the three parties, the production of STT3930 was successfully completed.

In-plant acceptance

On January 21, 2019, the Second Bureau of CCCC organized a number of domestic industry experts and representatives of third-party supervision companies to conduct in-plant acceptance of the STT3930-200t tower crane in Yongmao Construction Machinery. Industry information query, and finally determined that the STT3930-200 tower crane as a whole passed the inspection and acceptance of experts in the factory.

On-site tower lift

In April 2019, Yongmao STT3930-200t super-large flat-top tower crane installed a vertical tower at the construction site of the cross-river bridge project in the west section of Nanjing Puyi Highway. Yongmao appointed a professional technical team to participate in the whole process. After installation guidance, attachment guidance, jacking After the guidance and process maintenance service, the STT3930 tower crane was successfully delivered and put into use. Due to the small section size of the STT3930 standard section, it is possible to share the bearing platform with the cable tower as the foundation, saving the cost of independent construction of the foundation. The blind area of horizontal and vertical hoisting is 5.5m and 6.1m respectively, which is convenient for hoisting and quick positioning. The hook is lightweight and can be hoisted into small spaces. The lifting design is simple and the installation efficiency is high. It only takes 2 hours to lift a single section. The attachment design is simple and the installation efficiency is high, and it only takes 4 hours for a single attachment installation. The overall performance of STT3930 during the construction of the project was excellent, and the structural capping task was completed at least 15 days ahead of schedule, which was unanimously praised by the client and the construction party.

Final acceptance

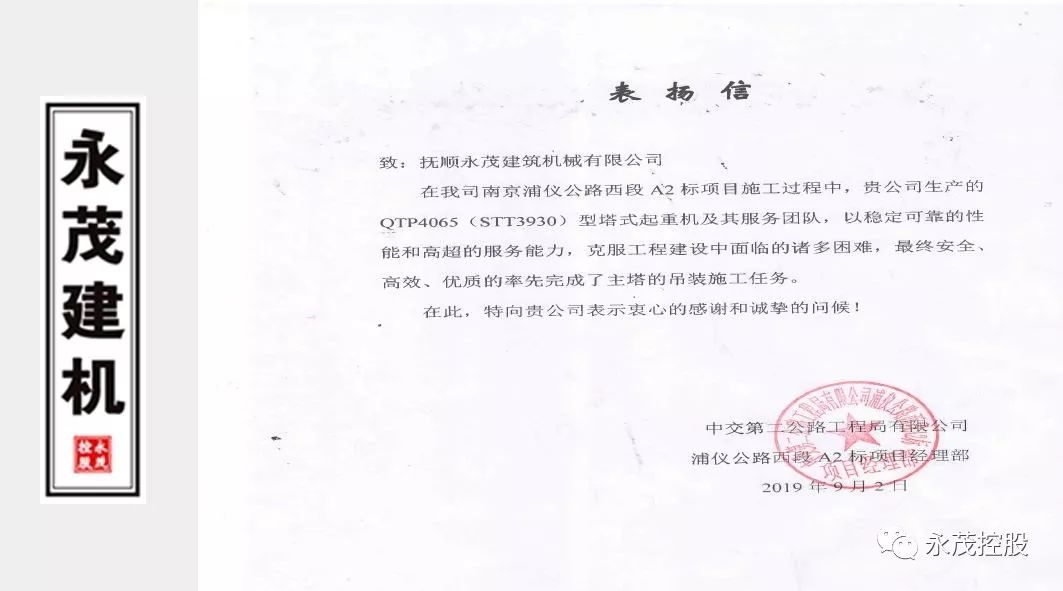

On August 20, 2019, the STT3930-200t super-large flat-top tower crane of Fushun Yongmao Construction Machinery Co., Ltd. completed the hoisting of five steel tower segments within 30 days during the construction of the main bridge project of the A2 section of the Nanjing Puyi Yangtze River Highway Bridge. Construction site inspection, internal industry data review, expert group evaluation, the inspection results meet the contract requirements, and successfully passed the on-site acceptance of CCCC Second Highway Engineering Bureau Co., Ltd.

Postscript

As one of the top ten tower crane manufacturers in the world, Yongmao large and super large tower cranes have provided excellent technical support, excellent product quality and good after-sales service for many projects around the world. This time Yongmao STT3930 successfully passed the product acceptance, marking that the cooperation between CCCC Second Public Office and Yongmao has entered a new stage of development. It shows the strength and level of Yongmao brand that is comparable to international machinery giants. In the future, Yongmao will walk side by side with China's bridge construction cause and make positive contributions to the great cause of "building a beautiful China".

STT3930-200tproduct description

The world's largest flat-top tower crane STT3930-200t, with a maximum boom length of 90m and a maximum lifting capacity of 200t. The product adopts a new trapezoidal boom design, with strong lifting performance, leading the world in full-load lifting speed, greatly improving construction efficiency, and perfectly matching various working conditions. Self-adaptive synchronous double hoisting mechanism, intelligent switching magnification, PLC control center whole-process control system, real-time data reception with display, early warning, anti-control, and fault self-diagnosis functions. The integration of safety monitoring and human-computer interaction enables easy ground operation and precise positioning. Integrating a number of industry-leading independent core technologies, the product is stable, convenient, intelligent and efficient, especially suitable for the construction of large-scale bridge projects.